THE CHALLENGE

During a planned well intervention to recover a parted packer, operations were disrupted when the Releasable Fishing Spear parted, leaving all four slips downhole. This unexpected setback posed a significant challenge, as the remaining slips obstructed further attempts to retrieve the packer assembly.

Oilenco was contacted to urgently mobilise specialist fishing tooling to assist in the recovery of the slips. A 3.700” Overshot Magnet, fitted with a 2.000” internal magnet, was run to depth of 9,624 ft and successfully recovered three of the four slips.

However, a subsequent run using a Lead Impression Block revealed the fourth slip was lodged in the annular space between the packer (2.688” OD) and the tubing (3.958” ID), preventing further progress.

Oilenco was tasked with designing a bespoke tool capable of navigating the restricted annular space and retrieving the final slip - thereby enabling full recovery of the lower half of the packer.

THE SOLUTION

After detailed discussions with the client, a hook-style retrieval mechanism was identified as the most viable solution. Within 25 hours, Oilenco presented a design concept for a custom tool, which was immediately approved by the client for manufacture.

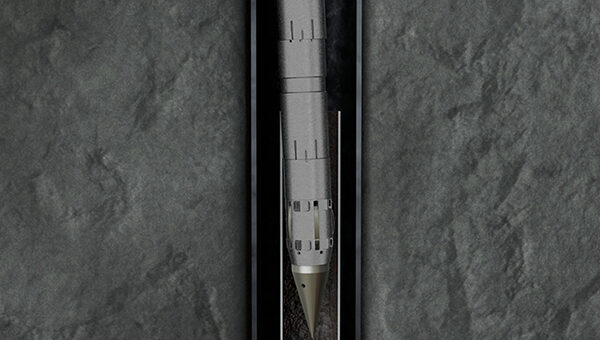

24 hours later, the 3.750” Tool Carrier with custom Hook Grapple was manufactured in-house and dispatched to the heliport for immediate offshore mobilisation. Once offshore, the tool was deployed in conjunction with Oilenco’s 2.500” Rotator Tool, providing the controlled rotation to position and manipulate the hooks on the Grapple. The Grapple’s geometery was specifically engineered to navigate beneath the lodged slip and then rotate into engagement. For added assurance during recovery, a 2.000” internal magnet was integrated within the Tool Carrier to provide additional holding force once the slip was engaged.

VALUE CREATED

Sixty-two hours after the initial concept discussion, the final slip was successfully recovered to surface - held securely inside the Hook Grapple by the internal magnet.

This rapid turnaround was made possible by Oilenco’s agile engineering approach, in-house machining capabilities, and close collaboration with the client.

The bespoke solution not only addressed a complex downhole challenge but also reduced operational downtime, enabling the client to resume their well intervention programme with minimal disruption. Oilenco’s ability to deliver innovative, fit-for-purpose tooling under tight time constraints highlights the value of responsive engineering and tailored intervention support in critical offshore operations.

FURTHER INFORMATION

call +44 (0)1224 548700 or email info@oilenco.com